Dingdian Yan a b, Luanxiao Zhao a b, Minghui Lu c, Yonghao Zhang d, Min Chen a b, Fengshou Zhang e

aState Key Laboratory of Marine Geology, Tongji University, Shanghai, 200092, China

bSchool of Ocean and Earth Science, Tongji University, Shanghai, 200092, China

cResearch Institute of Petroleum Exploration & Development, PetroChina, Beijing, 100083, China

dChina National Logging Corporation, Xi'an, 710077, China

eKey Laboratory of Geotechnical & Underground Engineering of Ministry of Education, Tongji University, Shanghai, 200092, China

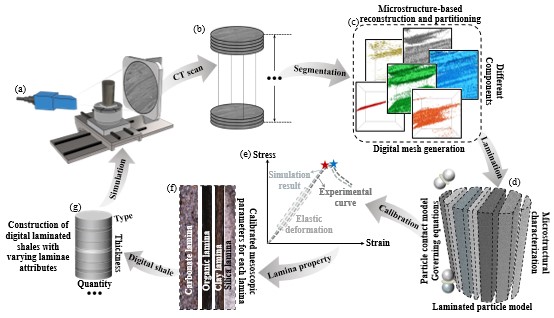

Abstract:Sedimentary rocks with well-developed laminated structures, such as shales, exhibit intricate mechanical responses driven by the variability and heterogeneity of lamina attributes. Quantifying the influence of individual lamina attributes on rock mechanical responses is essential for understanding the complex deformation and failure mechanisms of laminated shales, with broad implications for geo-applications across Earth sciences and energy fields. However, precisely decoupling lamina-related variables in rock experiments is challenging. We develop a digital rock workflow that reconstructs internal fabric and lamina characteristics by integrating CT-derived shale microstructures with a discrete element method-based laminated particle model, with contact parameters for each lamina type calibrated using experimental data. Simulation results show that increasing soft laminae (clay) quantity reduces strength by 15 % and modulus by 35 %, while greater thickness lowers strength by 35 % and halves the modulus, both raising Poisson's ratio. Conversely, shales interspersed with stiff laminae (silica) exhibit the opposite variation. Variations in lamina properties significantly affect microcracking behavior during failure, complicating the damage mode. Increased lamina quantity and thickness amplify the complexity of microcrack evolution, with soft laminae playing a dominant role by facilitating shear slip and promoting shear failure. Analysis of internal stress characteristics within soft and stiff laminae, boundary regions, and the rock matrix reveals that these mechanical variations in laminated shale stem from stress mismatches across these structural components. The greater the disparity, the stronger the mechanical contrast, amplifying localized deformation and failure complexity. Our simulations align well with experimental data, highlighting the potential of digital shale modeling to quantitatively link rock mechanical properties with lamina attributes while providing a crucial micro-mechanical perspective.